Among all the challenges ahead of us, there is one we need to tackle with an open mind for unconventional solutions and new technologies – the plastic challenge.

Modern medicine, auto parts, lightweight aircraft materials, satellites and internet technology – all this wouldn’t be possible without plastics.

But its impact doesn’t stop there.

By 2050, according to the Center for International Environmental Law, production and incineration of plastics could be responsible for emitting nearly 56 billion tonnes of carbon dioxide – one of the elements that’s destroying our planet if there is too much of it.

In short, we still need plastics, but must get rid of the CO2!

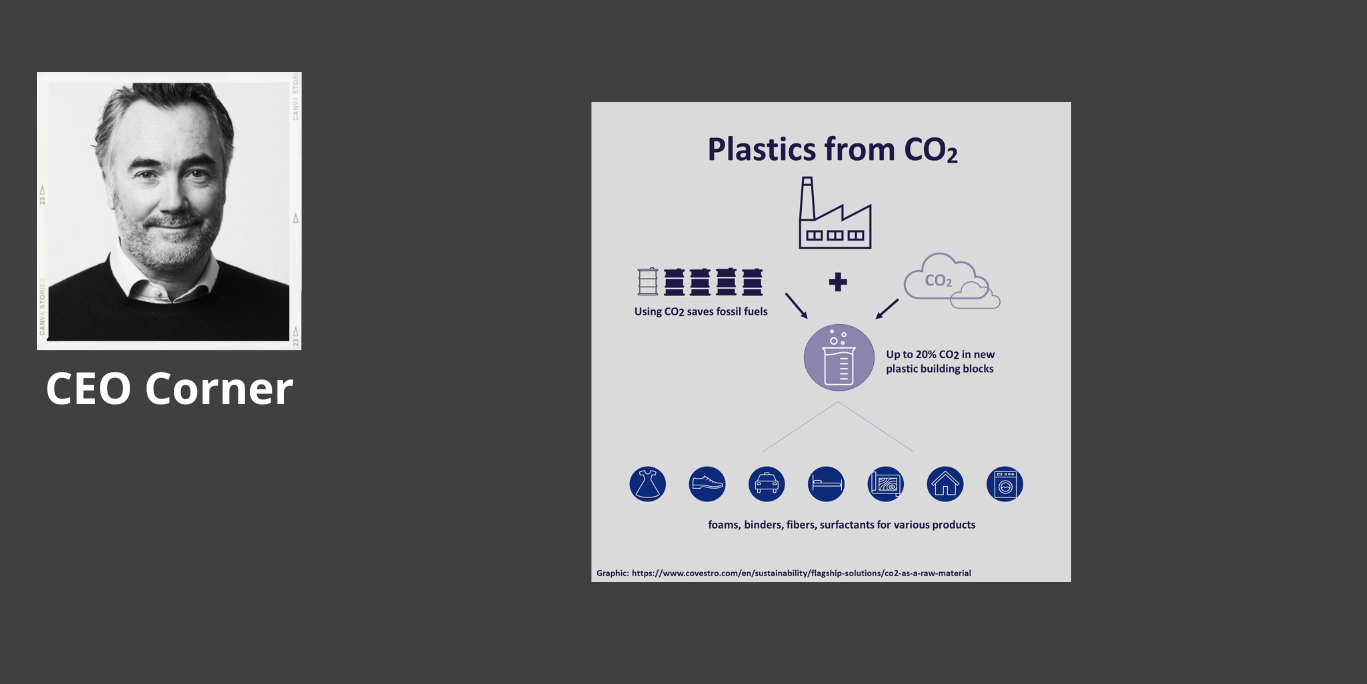

There might be a new way out of this dilemma – since rise and fall are close to each other. For almost a decade, scientists have been working on technology that is able to turn harmful carbon dioxide into feedstock for plastic production and partly replace petroleum in many products from automotive to textiles. With the help of an innovative catalyst developed by the German company Covestro together with RWTH Aachen University and the CAT Catalytic Center, up to 20 percent carbon dioxide can be chemically converted into polyol, a key precursor for polyurethane plastics such as foams or binders.

This carbon capture and utilization process removes not only CO2 from the atmosphere but reduces the use of fossil fuels in plastic production.

Finding a way of capturing industrial emissions is a great chance for emission heavy industries (chemical, steel and cement), who cannot avoid CO2 emissions so easily.

Research and development and an openness towards new technologies are our best strategies to slow down climate change – by implementing a circular economy across all sectors.

–

This is from a LinkedIn post by Jan Patrick Schulz, Landbell Group’s CEO. Check out all his posts here.

Sign up for our monthly

report COMPASS here:

Your email